The first part of the week was spent getting the greenware cleaned up for firing.

Once that was done, I started cleaning and clearing the work space for glazing.

I almost couldn’t believe it when I took the last mould off the work table Friday afternoon. The sweat was just pouring off my body as I moved it to its temporary new home.

The studio was like a furnace that day with the heat thrown off from two overnight bisque firings. I opened the studio door at 5:30 A.M. and turned on an electric fan to get the air moving while it was still cool outside. It was stifling in there anyway. While I am not really one of those guys who works shirtless, I made an exception.

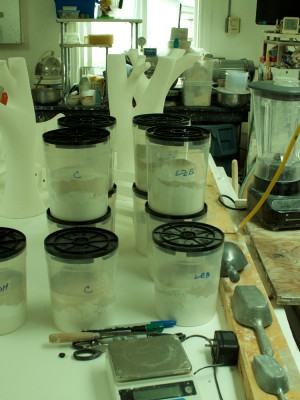

I purchased a couple more buckets the same size as the one I made the big batch of slip in. They now hold most of the project moulds. First I had to displace an equal volume of goods from the studio. I was left with a real sense of accomplishment that day. Now if I could only reclaim my slab roller.

Saturday and half way into Sunday, I mixed glazes. About twenty colours in all. What works for me is to first weigh a number of 1000 gram dry batches with brushing media for each base glaze I will be using. From there I add stains and oxides. Then each batch is put in the blender with 725 grams of water. When you are using brushing media, both it and the water content must be carefully controlled.

I sieve each batch of glaze twice through 80 and once through 120.

Polymers and the like are added after sieving. Otherwise you would just be pulling them back out.

Choosing the additives for a glaze is a bit like seasoning a plain soup. Some additives will give texture, some that extra complexity of flavour and some will transform the taste entirely.

For the trees I wanted texture that would reference bark in an abstract way. I chose iron filings, granular ilmenite and fine particles of a couple glaze polymers to design a dark speckled surface. I gave the glaze for the base the same additives. While differentiated by colour, tree and base will be unified by surface.

The glazes for the bench reference my early bench tiles from the previous decade. No additives other than oxides and stains. I want the bench to stand in contrast to the furry glaze.

I am going with a pink fake fur type glaze for the cat. What could be more friendly than a furry pink cat?

Taking my chances with the bear using an untested white fur glaze. In theory it should be beautiful. It’s like my other fur glazes but with all the colour, except a pale blue grey, stripped away. A polar bear.

Started glazing Sunday afternoon. Unloaded the second round of bisques today (Monday). The last piece of greenware is in the bisque and the first glazed piece is in the high fire as of the end of the day today.

Just barely over one week until show time. Trying not to stress, just to stay focused and get the job done.