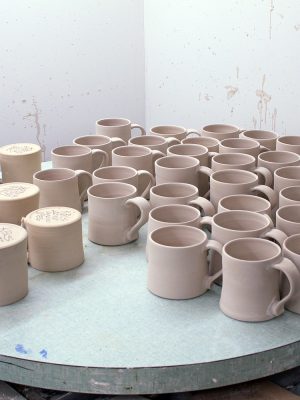

The thrown mugs from last week needed to be trimmed. Handles had to be made, attached to the forms and then cleaned up. Necessary steps in getting to the finished product.

The handles are a hybrid of different processes. Lengths of extruded strap were laid on the cutting mat and divide it into uniform lengths. Then each length was pulled into a taper and laid over a plaster form to set.

The forms I used as drape moulds for these handles were made by a process known as ‘sledging’. Wet plaster is given shape by dragging a template across it. I added the extra step of pulling because I am finding the extruded strap handles too chunky on their own for my current aesthetic.

As much as I would like to throw this coming week, I need to get started on glazing. Thinking plain colours suitable for image transfers. Sepia tone laser decals to start. Looking to have finished mugs by month’s end.